Simplify Workflow with Aftermarket Construction Parts

Simplify Workflow with Aftermarket Construction Parts

Blog Article

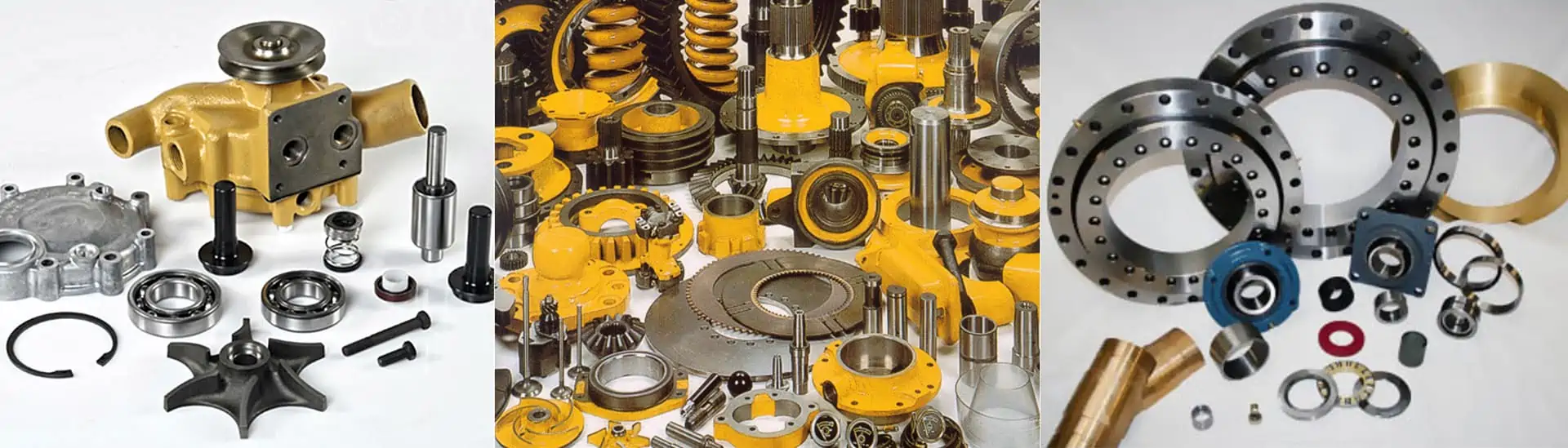

Boost Performance With Costs Aftermarket Building And Construction Parts for Heavy Equipment

Advantages of Premium Aftermarket Components

When considering hefty equipment upkeep, choosing costs aftermarket components provides significant benefits in regards to cost-effectiveness and efficiency reliability. Costs aftermarket parts are developed to satisfy or exceed the original tools producer (OEM) requirements, ensuring a high level of top quality and compatibility. These parts are usually more affordable than their OEM equivalents, making them an economical solution for businesses seeking to keep their heavy equipment without compromising on efficiency.

Construction sites and commercial setups can be extreme settings, placing tremendous anxiety on machinery components. By choosing costs aftermarket components, services can minimize downtime, decrease maintenance prices, and make sure that their machinery operates at peak efficiency.

Enhancing Equipment Efficiency

One of the substantial benefits of using costs aftermarket components for hefty machinery upkeep is the enhancement they bring to equipment performance sought after functional atmospheres. By selecting high-quality aftermarket components, equipment operators can experience better effectiveness, productivity, and general efficiency of their tools. Premium aftermarket components are specifically developed to satisfy or also surpass the standards set by original equipment makers (OEMs), making sure that hefty machinery runs at peak levels. These components are crafted with accuracy and longevity in mind, offering improved integrity and longevity to the machinery they are installed in. In addition, premium aftermarket components can help maximize fuel intake, decrease downtime for repair services, and lessen the threat of unexpected failures, ultimately leading to a smoother and a lot more reliable operation of heavy equipment in different building and construction and industrial setups. Purchasing premium aftermarket parts is a calculated selection for firms seeking to enhance the performance and durability of their heavy equipment fleet.

Affordable Solutions for Upgrades

Executing affordable services for upgrades in heavy machinery maintenance can considerably affect operational efficiency and overall efficiency. When thinking about upgrades, it's important to focus on investments that offer a balance between quality and cost-effectiveness. One cost-efficient remedy is going with premium aftermarket parts that provide comparable efficiency to original equipment supplier (OEM) parts but at a reduced price factor. These aftermarket parts undergo strenuous screening to guarantee they meet sector requirements and specifications, making them a trustworthy option for machinery upgrades.

Regular upkeep and timely upgrades can assist protect against pricey downtime and prolong the life-span of heavy machinery. One more cost-effective approach is to spend in technology upgrades, such as telematics systems, which can improve devices monitoring and performance optimization - aftermarket construction parts. These systems allow real-time monitoring of equipment health metrics, enabling proactive maintenance and lessening the danger of unforeseen failures

Raising Machinery Longevity

Enhancing the toughness of heavy equipment is critical for making visit this page the most of operational efficiency and minimizing overall maintenance expenses. Making use of top notch aftermarket parts particularly made for heavy equipment can also add to extending the life-span of devices. By prioritizing equipment longevity through a combination of preventive maintenance methods and top quality aftermarket components, Related Site construction business can improve the effectiveness and cost-effectiveness of their operations while decreasing downtime due to unforeseen failures.

Optimizing Equipment Functionality

To ensure the peak performance of hefty machinery, maximizing equipment functionality is crucial for building firms aiming to make best use of operational efficiency and lessen downtime. One vital aspect of optimizing machinery functionality is performing regular upkeep checks to recognize and address any kind of potential issues before they escalate. Implementing a preventative maintenance timetable can aid in detecting worn-out components or components that may hinder the equipment's efficiency. Additionally, using sophisticated innovation systems and software application for keeping an eye on equipment health and wellness and performance metrics can provide real-time information understandings, enabling positive maintenance treatments.

Moreover, enhancing machinery capability includes ensuring that all drivers are adequately educated to operate the devices efficiently and safely. Offering recurring training sessions and refresher training courses can improve operator abilities, resulting in smoother procedures and minimized opportunities of failures because of human mistake. Integrating performance monitoring mechanisms can assist in reviewing machinery use patterns and determining locations for renovation or adjustment to enhance functionality. By focusing on machinery performance optimization, building and construction companies can boost productivity, extend equipment life-span, and ultimately accomplish greater returns on their hefty machinery investments.

Final Thought

When considering heavy machinery maintenance, choosing for costs aftermarket components offers significant advantages in terms of cost-effectiveness and performance reliability.One of the considerable benefits of using premium aftermarket components for heavy machinery upkeep is the enhancement they bring to machinery performance in demanding operational atmospheres.To make sure the peak performance of heavy machinery, optimizing machinery performance is crucial for construction companies aiming to make best use of operational efficiency and minimize downtime. By prioritizing equipment capability optimization, construction firms can boost performance, lengthen machinery life expectancy, and eventually achieve higher returns on their heavy machinery investments.

In verdict, making use of costs aftermarket building parts for heavy equipment offers many advantages, including boosted efficiency, economical upgrades, enhanced durability, and enhanced functionality.

Report this page